Key Services and Capabilities

Description

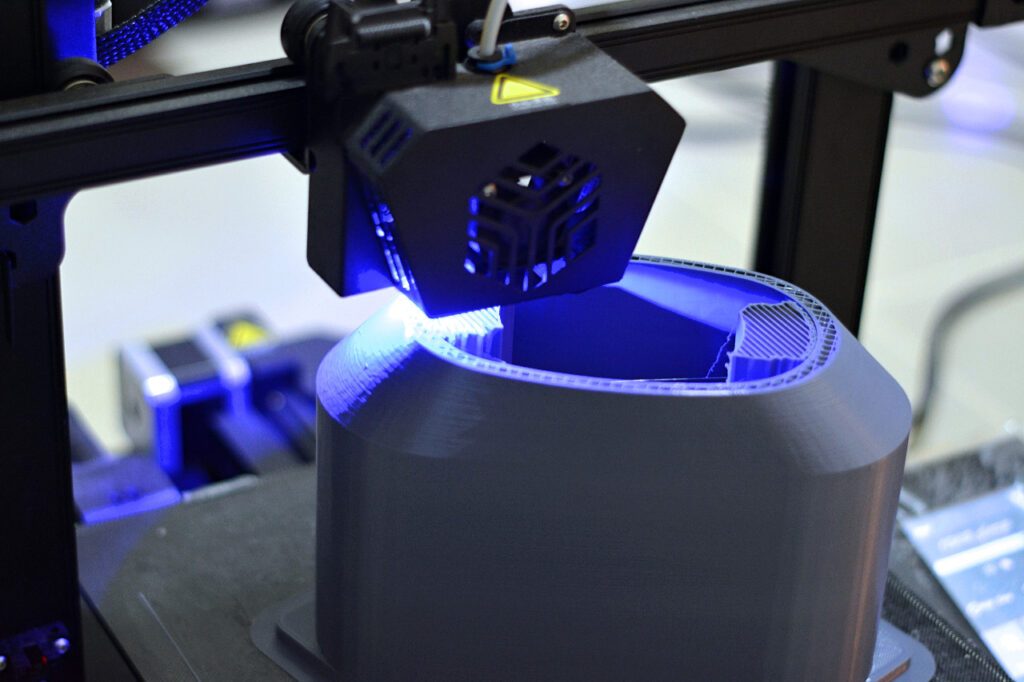

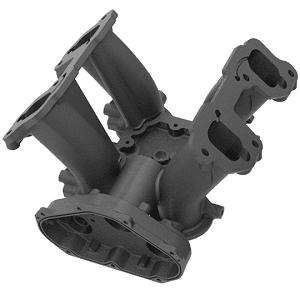

Traditional Manufacturing is defined as the creation and assembly of components and finished products using four main subtractive manufacturing methods – CNC Machining, Injection Moulding, Plastic Forming and Plastic Joining. The processes are long, they are fragmented and the supply chains are complex. 3D printing however is revolutionizing the way we create and manufacture products and allows to accelerate product development from concept or idea to the prototype and finished product all the while minimizing the impact on the environment. It offers a significant advantage for small, one-off production runs and the manufacture of complex pieces.

3DX AM is at the forefront of this cutting-edge technology. Our state-of-the-art 3D printers are capable of producing highly detailed and accurate parts, from concept to final product. With a wide range of materials to choose from we can create complex and customized products that were once impossible to make with traditional manufacturing methods.

The possibilities are truly endless. From prototypes to final products, we are constantly pushing the boundaries of what is possible. We are able to create complex geometries, unique designs, and customized products.

Services & Products

- Rapid Prototyping

- Low-Volume production

- 3D Designing

- Functional Prototyping

- Display Models

- Reverse Engineering

- Digital Warehousing

Social Info

Location

Claim Your Business Listing Now!

Is this your business?

Claim your business to get contacted by customers and manage your information.

Claim Your Business Listing Now!